Description

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material, semi-products, finished products in an ordinary year, we are capable to produce according to drawing or sample provided by the customer, so as to present you a favourable cost-performance ratio…Welcome to visit our factory.

Product Details

Optimum parameters for the geometry of the reducing thing have been hooked up experimentally. They depend on the actual machining conditions, such as the material being worked; the cutting mode; the kind of cutter; the pressure of the system comprising the lathe, attachment, tool, and workpiece; the kind of machining; and the approach used to produce the workpiece billet. The superior parameters (see Figures 2, 3) are γ = - 10° to 25°, α = 6° to 12°, ɸ = 10° to 90°, ɸ1, = 0° to 20°, and λ =-4° to 15°.

When workpieces have machined the usage of a slicing device with an enlarged nostril radius r, the floor roughness is reduced, but the forces urgent the cutter away from the workpiece are increased; the reducing tool well-known shows expanded deflections, and there is more vibration. Therefore, the price of r is maintained at 1 mm. In order to simplify the sharpening of hard-alloy cutters, a cutter with a transitional reducing part 1-2 mm long with ɸ0= ɸ/2 is used as an alternative of one with a rounded nose. For cutters with mineral and ceramic blades, the following values are recommended: γ = –5° to - 10°, α = 8° to 10° and ɸ = 75° to 90° for smooth workpieces and ɸ = 10° to 30° for hard workpieces.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

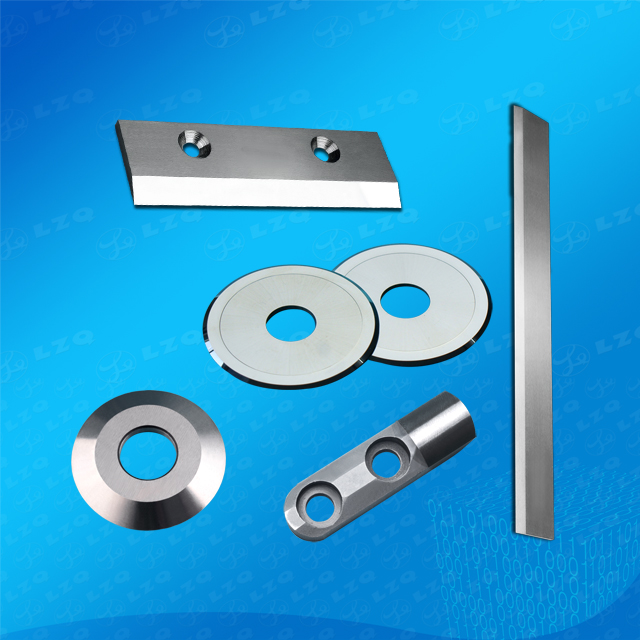

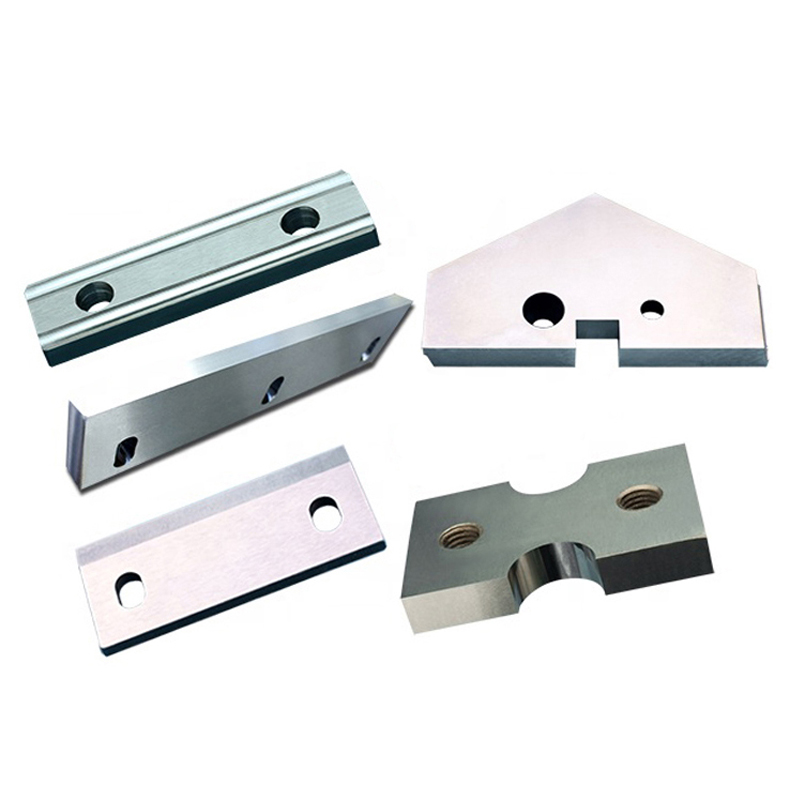

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.