Product Details

Material:

1. Ultra-high rust-resistant stainless steel & titanium alloy, conventional type with general rigidity (A)

2. Ultra high rust-proof high wear-resistant stainless steelseries (HRC54±°2°Section), ultra-high rigidity.

Revolutionary corrosion resistant coating helps increase efficacy over time. Enhanced visibility - Labels indicate the remaining length of the drill (from drill tip to stopper top). Each stopper is anodized and color coded. Labels are laser etched. We can etch the specifications on stoppers just according to your any specific requirement.

Technical and biomechanical skills of our engineers enabling to guarantee the resistance of the component and their adaptation to the oral environment thanks to modern means of simulation.

Since then implants have evolved into three basic types:

1. Root structure implants; the most frequent type of implant indicated for all uses. Within the root form kind of implant, there are roughly 18 variants, all made of titanium but with specific shapes and surface textures. There is restricted proof showing that implants with relatively easy surfaces are less inclined to peri-implantitis than implants with rougher surfaces and no proof displaying that any particular type of dental implant has foremost long-term success.

2. Small diameter implants are implants of low diameter with one piece construction (implant and abutment) that are sometimes used for denture retention or orthodontic anchorage.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

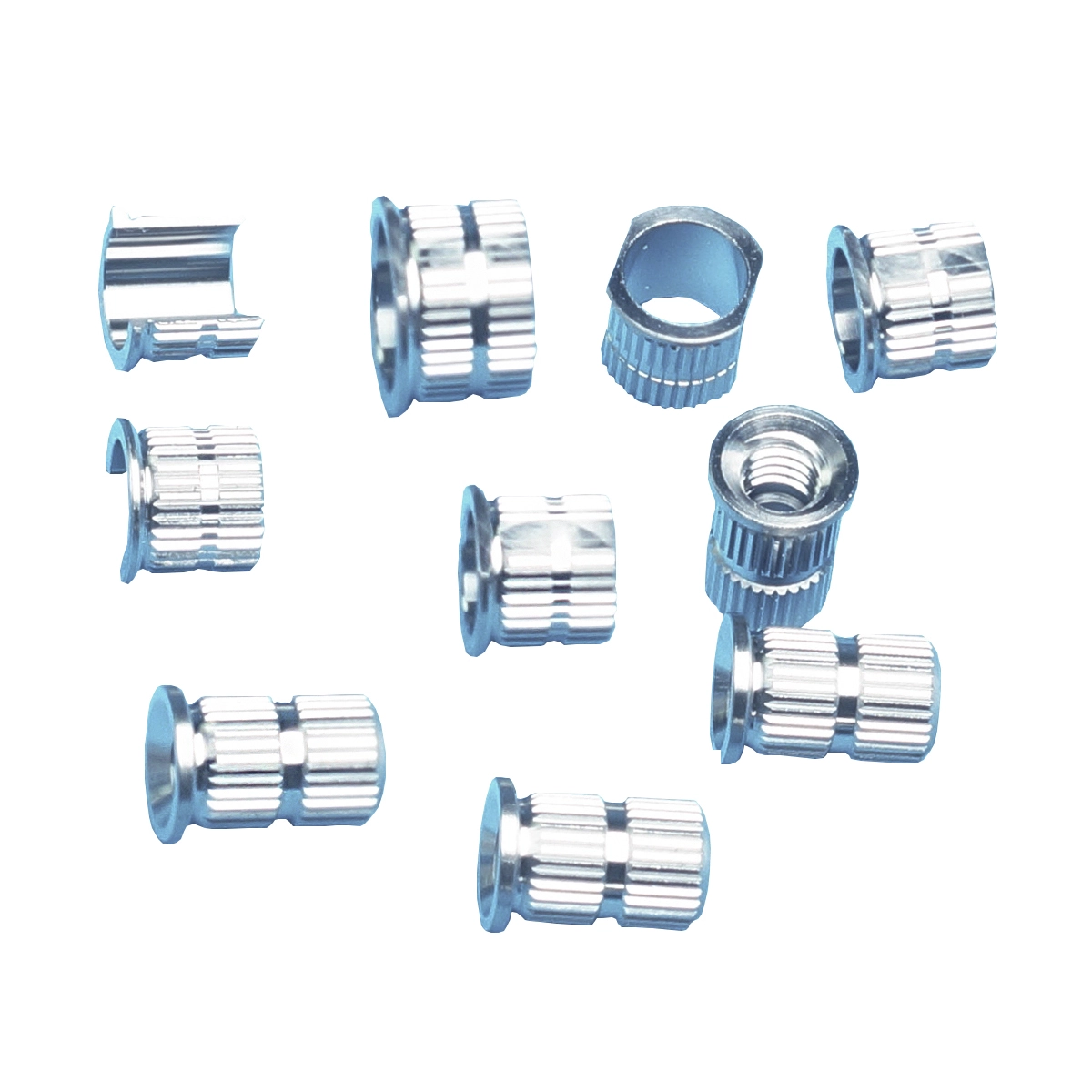

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.