dental implant Trepan drills Tissue punch Trephine bur

We specialize insuper-hardness machining for special,non-standard new items withdifferent size and tolerance. Possessed of cuttingedge & comprehensive production system, as well as rich producing & machining capability with different precision technology, so as to realize high efficiency application.

Ultra micro-grain, long cutting age,perfect durability, Can be made to order according to graph And sample.

Pilot drill + Trephine

one-to-one correspondence

non-slip

LZQ is an OEM factory for all kinds of medical tools

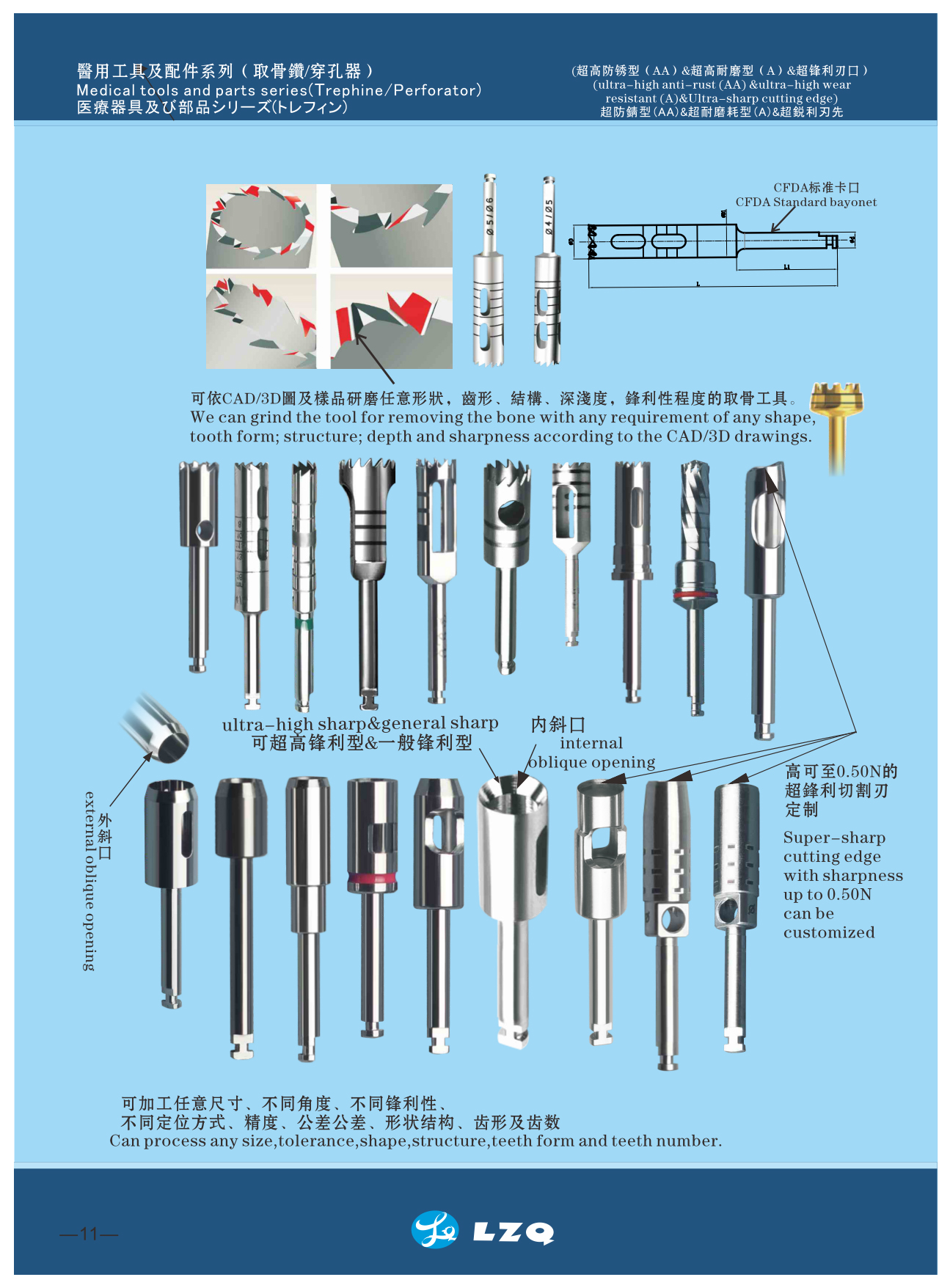

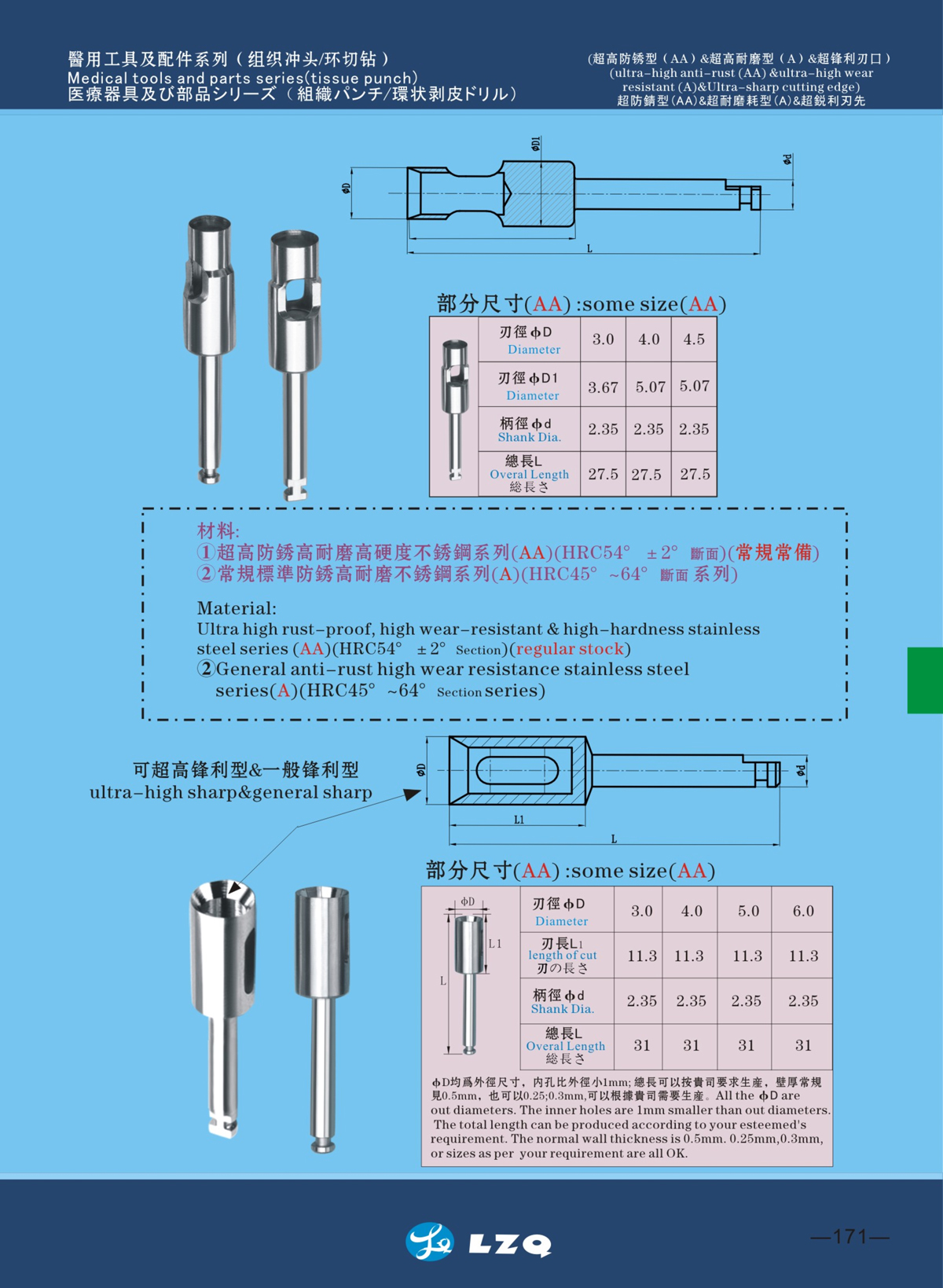

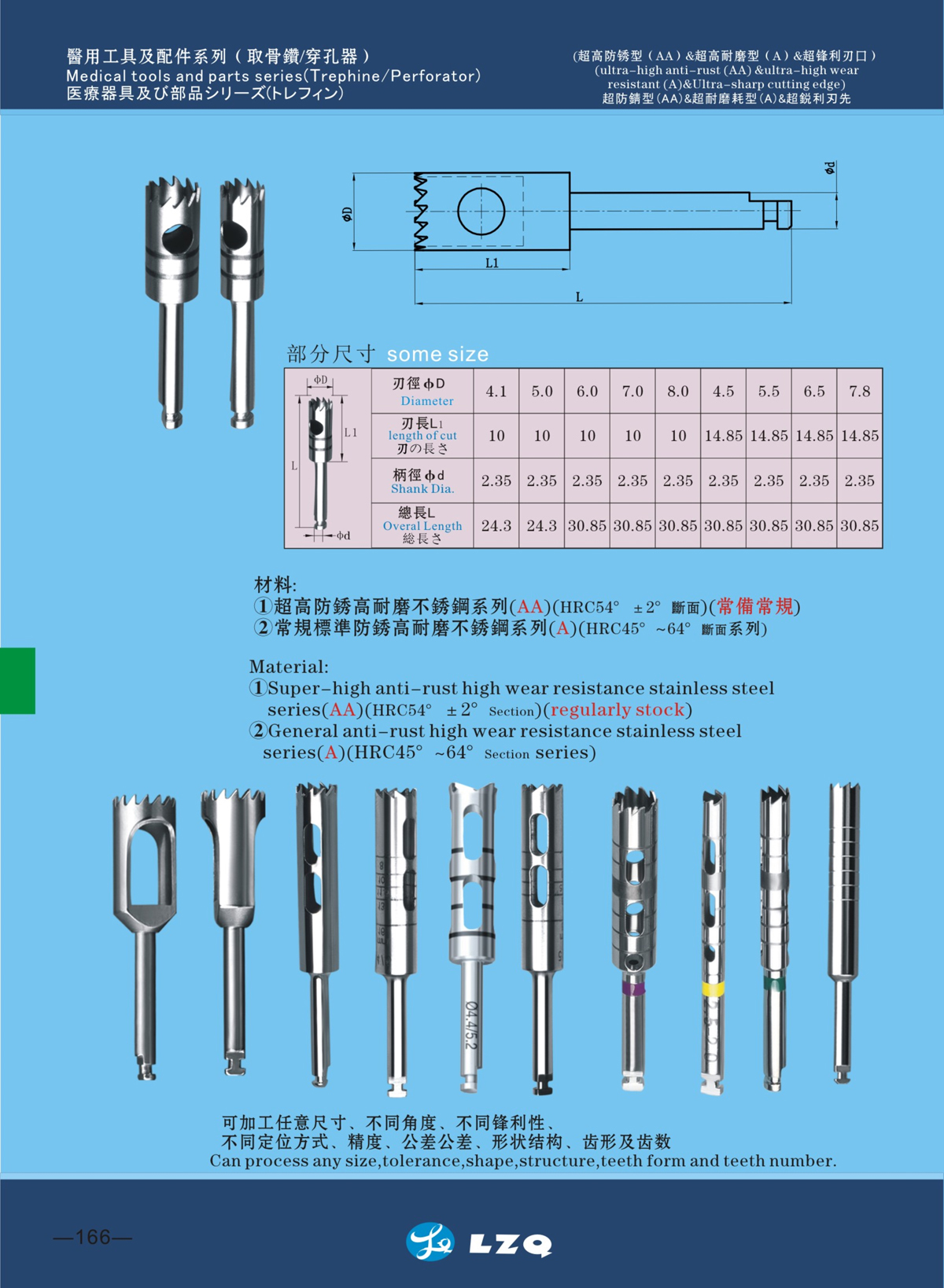

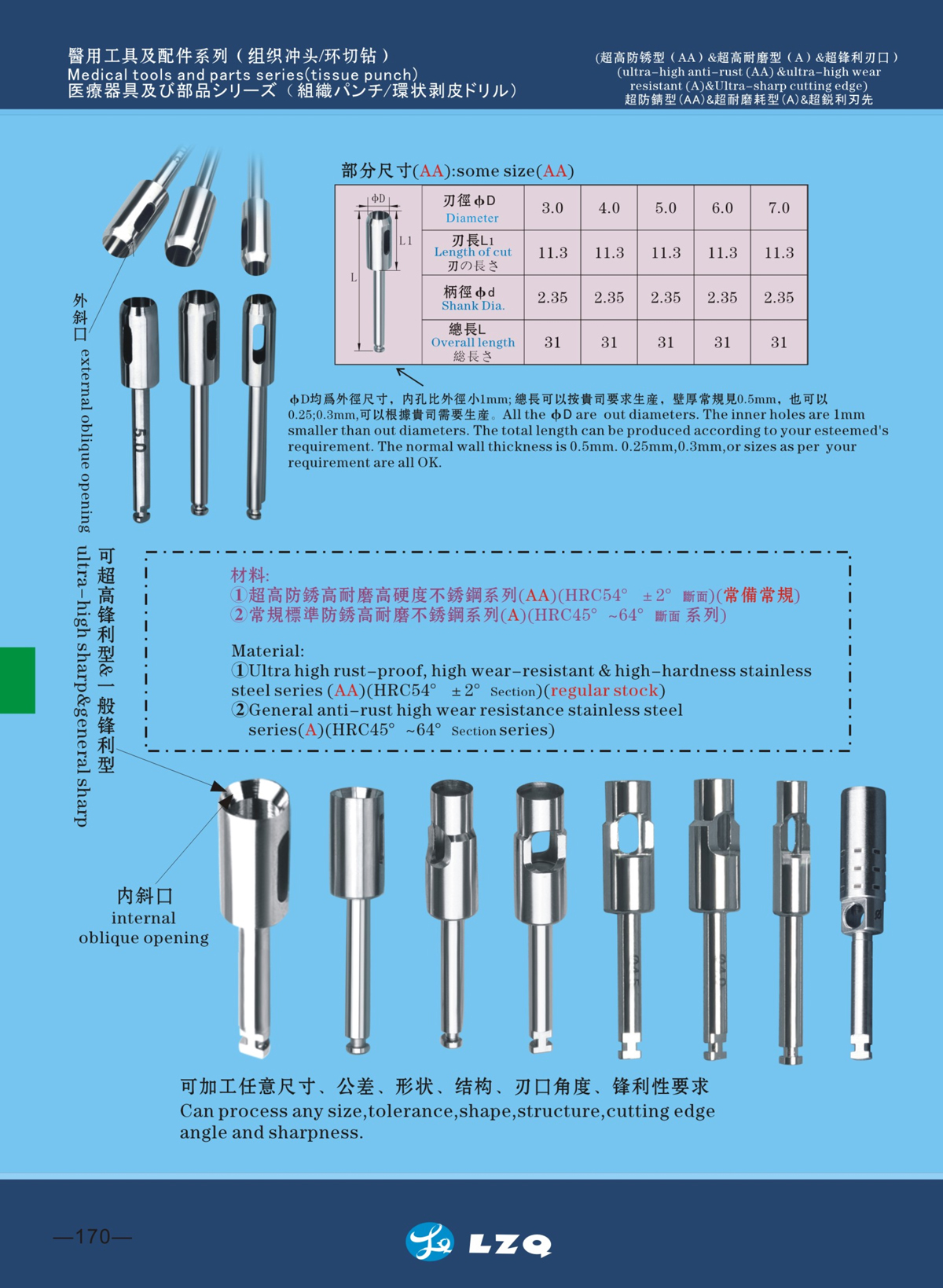

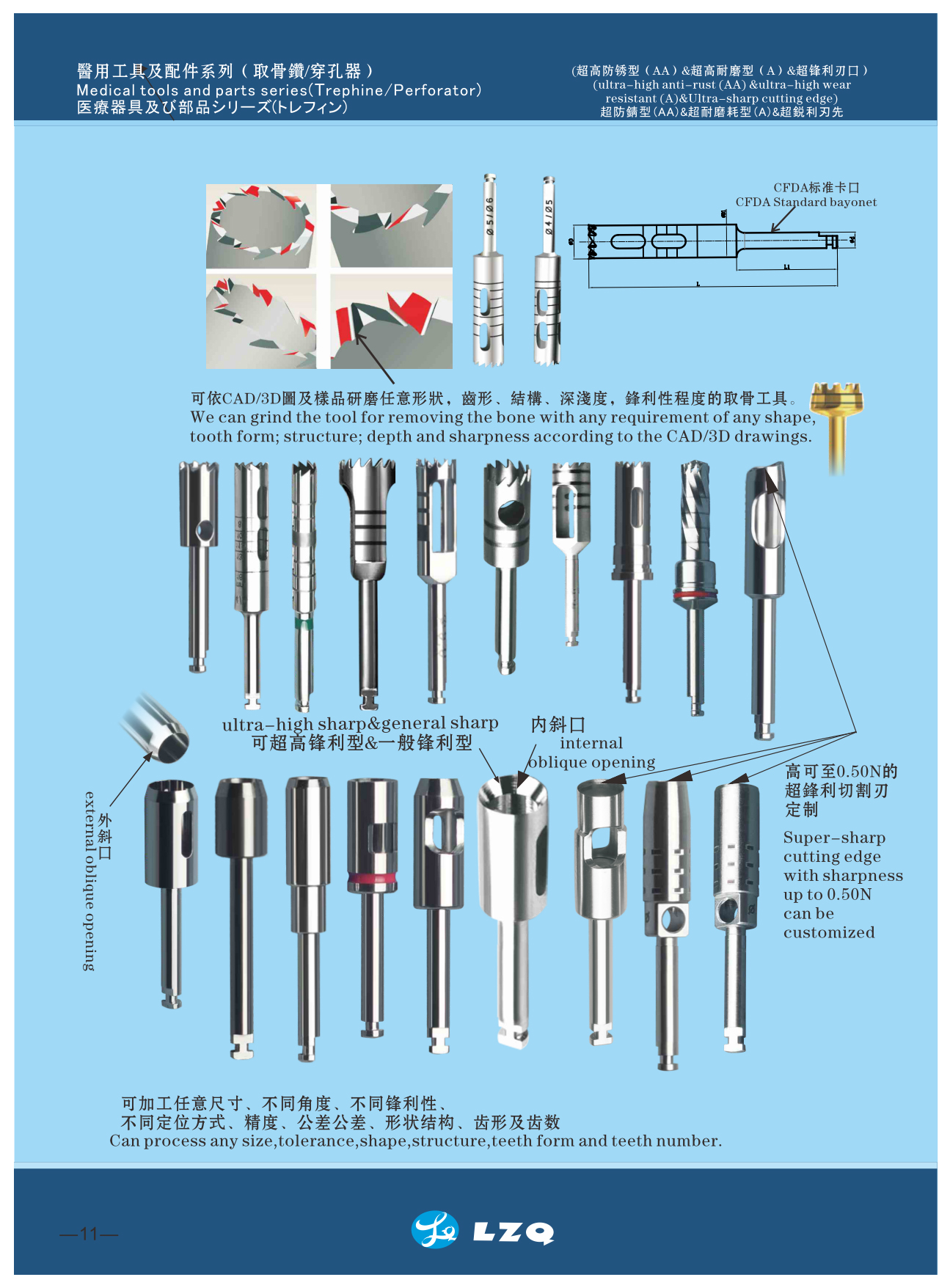

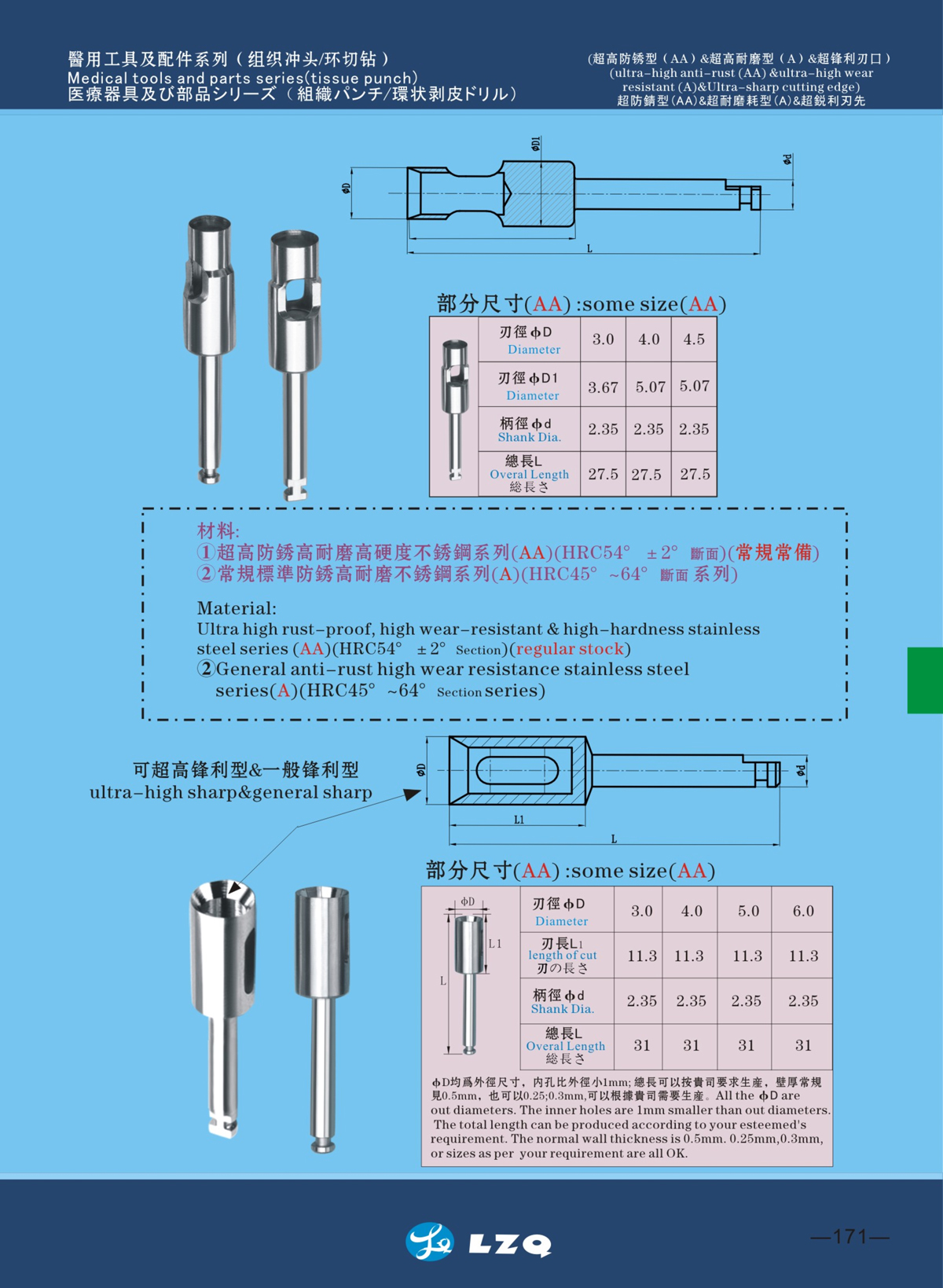

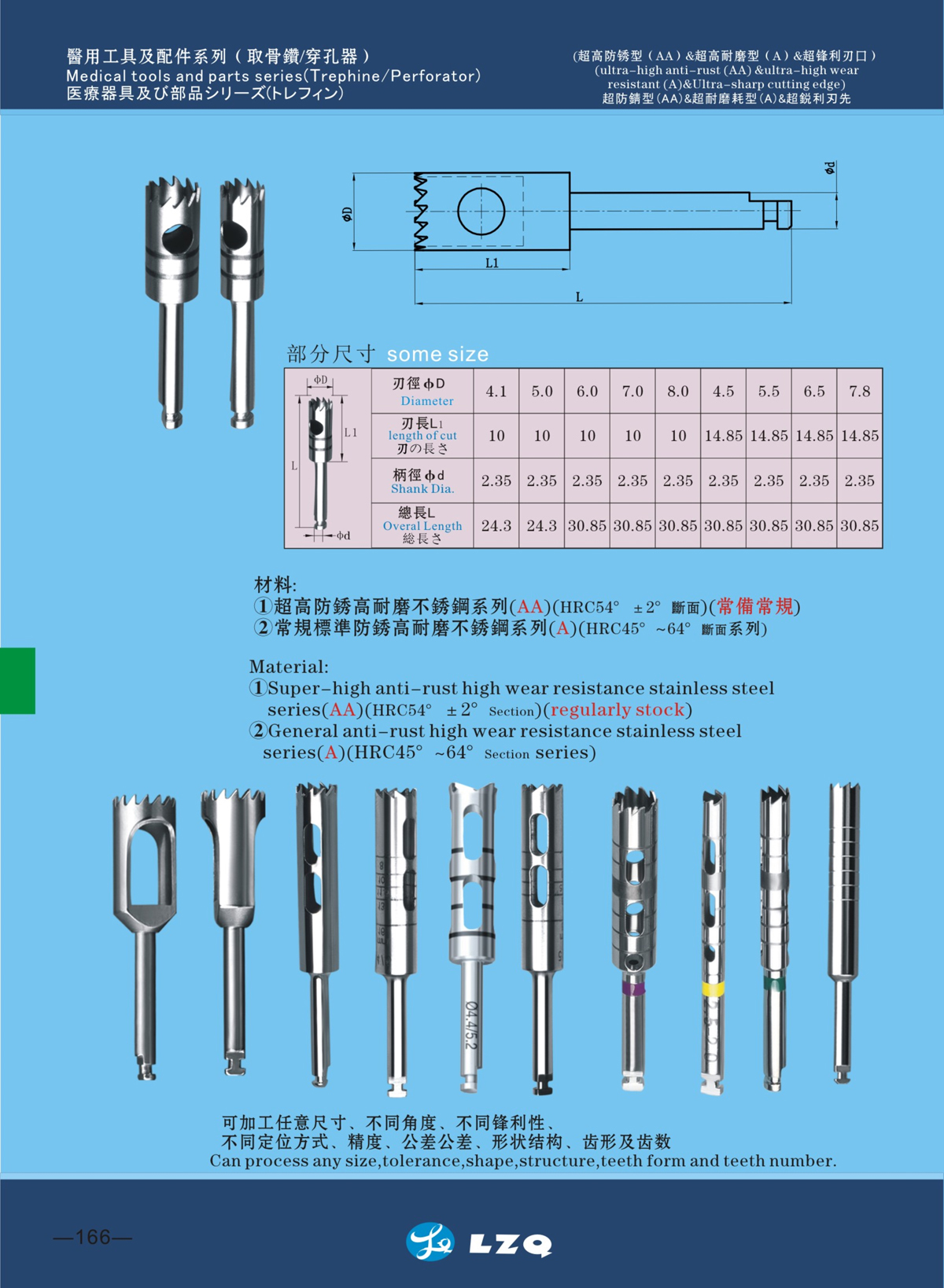

(ultra-high anti-rust (AA) &ultra-high wear resistant (A)&Ultra-sharp cutting edge)

Different cutting edge materials (ceramic, carbide, high anti-rust high grade stainless steel (AA), titanium and titanium alloys, conventional standard anti-rust high wear-resistant stainless steel (A) ...series) can be produced according to customers' requirement

Cutting edge machining grades:

Class AAA: CNC super hard grinding wheel,mirror surface grinding for any shape ofcutting edge.Concentricity, runout, cylindricityb≤0.003mm(3um),any sharpness of cutting edge.

Class A A: CNC super hard grinding wheel,finish grinding for anv shape of cutting edge.Concentricity runout,cylindricity ≤0.008mm(8pm),any sharpness of cutting edge.

Class A: CNC super hard grinding wheel, general grinding for any shape of cutting edge.Concentricity, runout,cylindricity≤0.012mm(12μm),any sharpness of cutting edge.

Class B : CNC lathe work + heat treatment+polishing treatment, worse sharpness of cutting edge.

Concentricity,runout, cylindricity(0.10~0.20mm)(100/μm~200/μm).

Material of cutting edge:

1. ultra-high anti-rust high wear-resistant stainless steel(AA)(HRC54°±2°Section)(regular stock)

2.general anti-rust high wear-resistant stainless steel(A)(HRC45°~64°Section)

3.Titanium and Titanium alloy (HRC35°~42°) series

4.Ceramic(HRA85°~94°)series,(HRC67°~84°) series

5. Carbide(HRA81°~94°) series,(HRC60°~84°) series

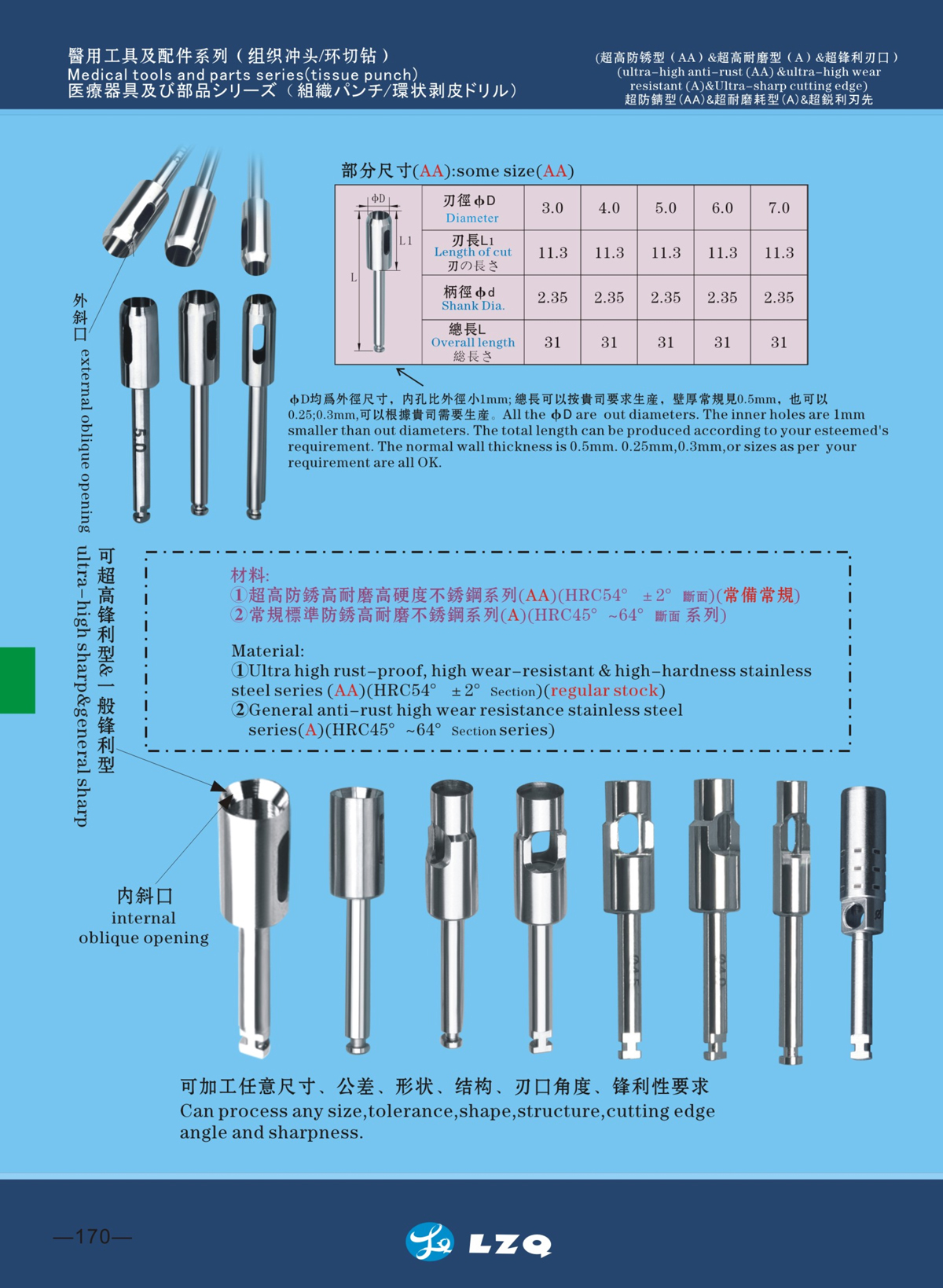

Can process any size,tolerance,shape,structure,teeth form and teeth number.

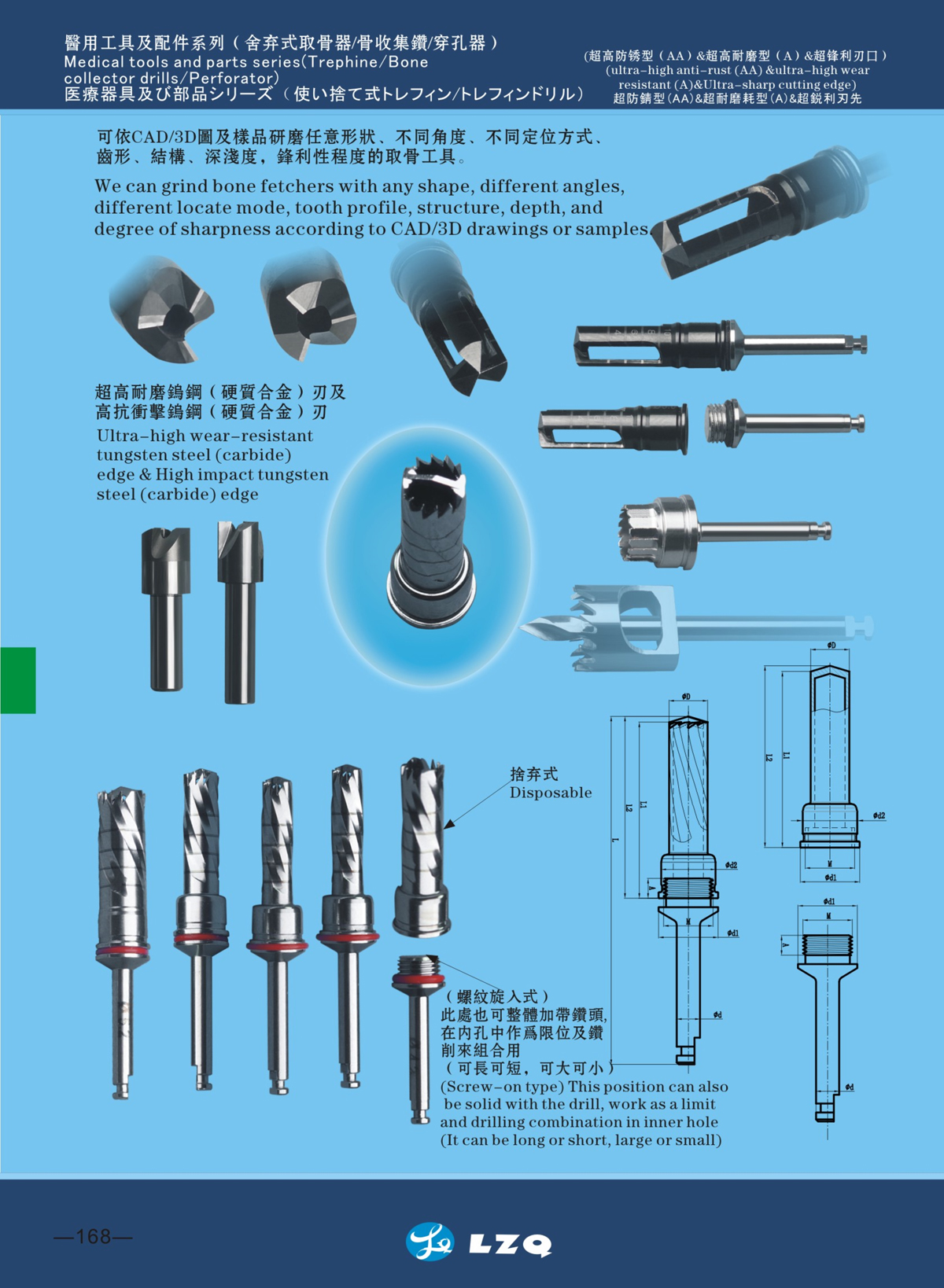

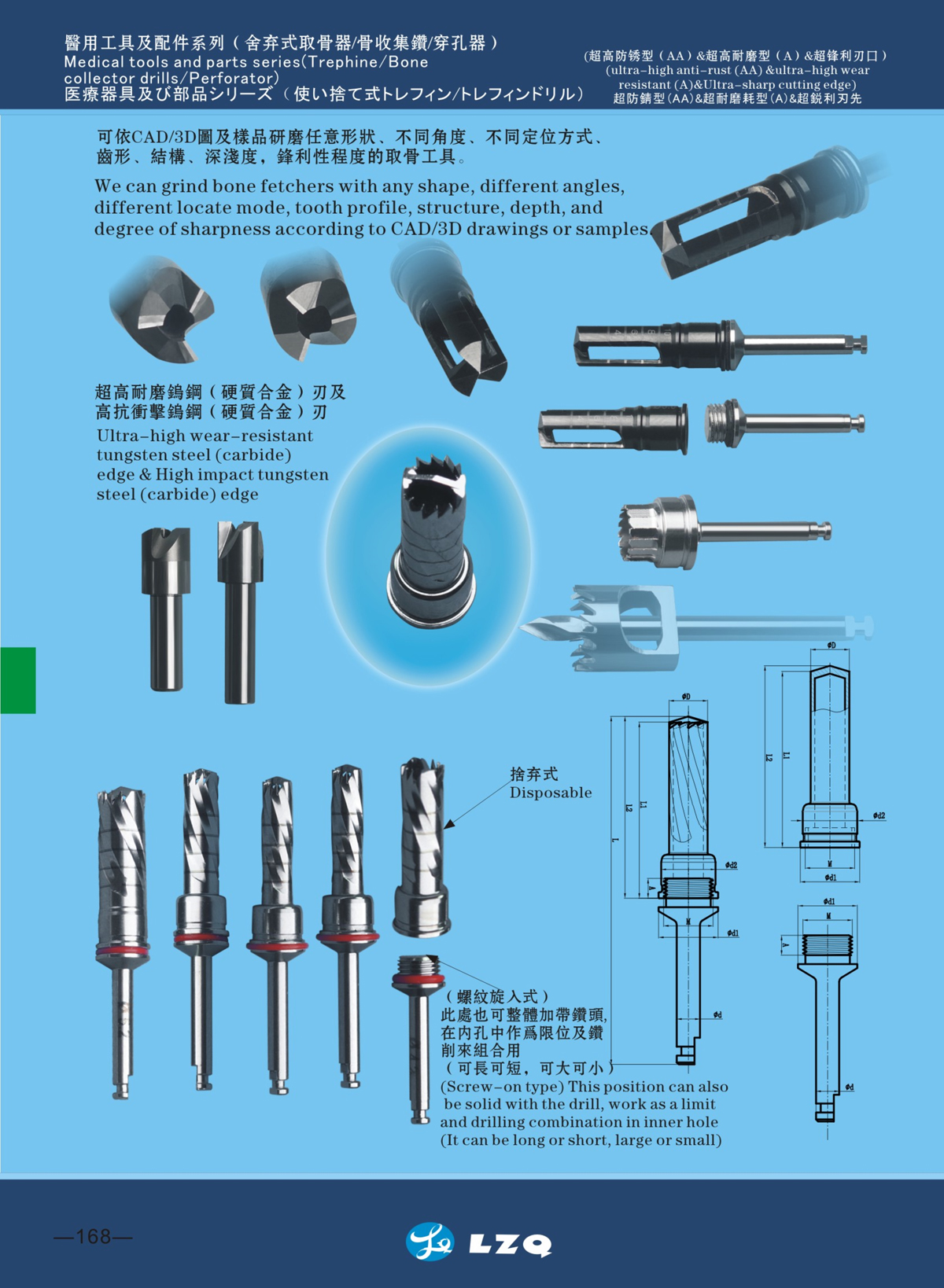

We can grind bone fetchers with any shape, different angles, different locate mode, tooth profile, structure, depth, and degree of sharpness according to CAD/3D drawings or samples.

Ultra-high wear-resistant tungsten steel(carbide)edge &High impact tungsten steel(carbide)edge

We can produce products with any requirement for angle of cutting edge, type, structure, degree of cutting edge, chip flute size.

ultra-high sharp&general sharp

Application domain: for dental implantology

Material:

(Ultra-high rust-proof stainless steel AA) (hardened HRC54 ° ± 2 ° Section)

Ultra-high anti-rust & high wear-resistant , high hardness, high impact, high toughness stainless steel, with excellent anti-rust capability, corrosion resistance, wear resistance (high hardness) performance and ideal impact resistance.. Its excellent corrosion resistance is comparable to TYPE 304 Stainless steel; and its rust resistance is closer to alloy for surgical implant. Unmarked, with 5% Neutral salt spray test (ASTM B117), it doesn't rust after 1000 hours. Wide range of applications, quite good and stable quality, which can be used to produce extremely complex, high-precision shank shapes and profile ultra-sharp edge structures.

Applied for high-end medical standard: AMS 5936 . MMPDS-01 . ASTM A693

ASTM A564 . ASTM F899-12

The Vitro (cytotoxicity) test verifies that the material does not have any potential cytotoxicity and therefore can safely contact human tissue, body fluids or blood, and meets all relevant allergy and skin irritation test standards.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.