Description

Super-hard processing of professional, special, non-standard, special shaped and new products with any kind, any shape and tolerance. If you have any similar inquiry, please fax us your address or call us to get samples in the photos and related catalogue for your reference (only a small amount is allowed).

We keep around RMB 20~30 Million turnover stock articles such as raw material, semi-products, finished products in an ordinary year, we are capable to produce according to drawing or sample provided by the customer, so as to present you a favourable cost-performance ratio…Welcome to visit our factory.

Product Details

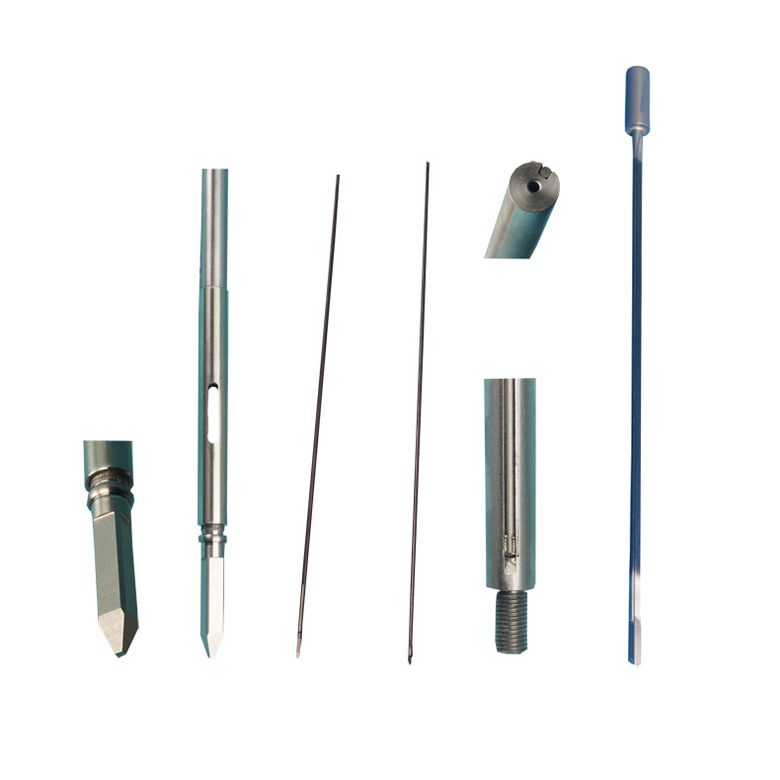

Super-hard drill bits for high hardness application. For other size specification and special micro-diameter, forming compound tooling, we can process according to drawings or samples. Machining case: φ8.50 mill diameter (emulsified liquid), SKD11(HRC62°), rotation speed 1600r/min, f≤199mm/min, the depth of drilled hole≤2.5*φD(mill Dia.), Precision of processed workpiece ≥h9, surface finish more than Ra1.6

Extra hard small diameter: mill Dia. φD (φ0.10-φ2.00mm), applicable for machining of quenched steel of HRC≤62° and various high hard materials, compound materials, the depth of drilled hole ≤6*φD(mill Dia.)A drill having deep helical grooves along the shank from the point.

(Tools) a drill bit having two helical grooves running from the point along the shank to clear swarf and cuttings. The twist drill bit is the type produced in the largest quantity today. It comprises a cutting point at the tip of a cylindrical shaft with helical flutes; the flutes act as an Archimedean screw and lift swarf out of the hole.

The twist drill bit was invented by Steven A. Morse of East Bridgewater, Massachusetts in 1861. The original method of manufacture was to cut two grooves in opposite sides of a round bar, then to twist the bar (giving the tool its name) to produce the helical flutes. Nowadays, the drill bit is usually made by rotating the bar while moving it past a grinding wheel to cut the flutes in the same manner as cutting helical gears.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.