We can make any material and any kind of products. HSS, HSS-Co Carbide, Al203, Si3N4, PCBN, PCD, ND…… We can produce straight flute, oblique flute, spiral flute etc. precise grinding machining.

Confirm machined materials, HRC, equipment rigidity (value), quantity, we can grind profile angle and dimensional tolerance according to drawings, samples, and requirements… only produce in batch, can completely replace international first-class products, having higher performance/price ratio.

Referencing Referencing to the page footer, please provide your detailed drawing and samples (Samples should be with the best performance) and specify the detailed specification, material type, size tolerance, drawing of semi-product and finished product, applied equipment, equipment value (RMB, to judge its market value is rigid or floating), monthly consumed quantity, type of original product and its deficiency,when you make inquiry. What is the processed material and its HRC?

A greater aggressive angle, such as ninety degrees, is applicable for very smooth plastics and different materials; it would wear swiftly in hard materials. Such a bit is usually self-starting and can cut very quickly. A shallower angle, such as a hundred and fifty degrees, is perfect for drilling steels and other more difficult materials. This fashion of bit requires a starter hole, however, does not bind or suffer untimely wear so long as an appropriate feed charge is used.

Drill bits with no factor attitude are used in conditions where a blind, flat-bottomed gap is required. These bits are very touchy to changes in lip angle, and even a moderate alternate can result in an inappropriately quick reducing drill bit that will suffer untimely wear.

+86-021-50327060

+86-021-50327060

zq@lzqtech.com

zq@lzqtech.com

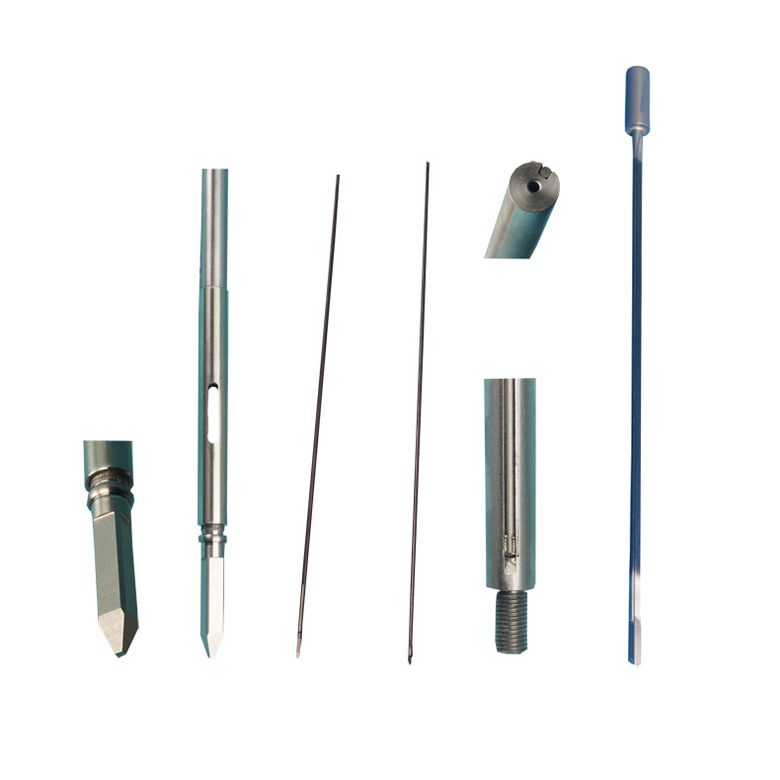

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE

Medical Instrument

We can achieve perfect edge quality and dimensional tolerance up to±0.0005mm (±0.5μm) in the process of micro, ultra-long, ultra-thin, super-abrasive, impact-resistant, high-precision and combined ... VIEW MORE Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE

Implant

Corresponding and matching drills and tools of different types, forms, shapes, structures can be high precisely ground to mold according to different brands and different types of implants forms, shap... VIEW MORE Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE

Cutting Tools

Super-hardness machining for special, non-standard new ite ms with different size and tolerance. VIEW MORE Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

Accessory Parts

we can customize for you according to your samples or drawings for any manufacturing of ceramic,carbide,stainless high-speed steel, stainless steel, titanium alloy, titanium diamond, etc series, hig... VIEW MORE

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.