一, Product Information

Super-hard

processing of professional, special, non-standard, special shaped and new products with any kind, any shape and

tolerance.

※If you have any similar inquiry,

please fax us your address or call us to get samples in the photos and related

catalogue for your reference (only a small amount is allowed). ※

We

keep around RMB 30~40 Million turnover stock articles such as raw material ,semi- products, finished products in

ordinary year , we are capable to produce according to drawing or sample provided by

customer, so as to present you a favorable cost-performance ratio…Welcome to visit our factory.

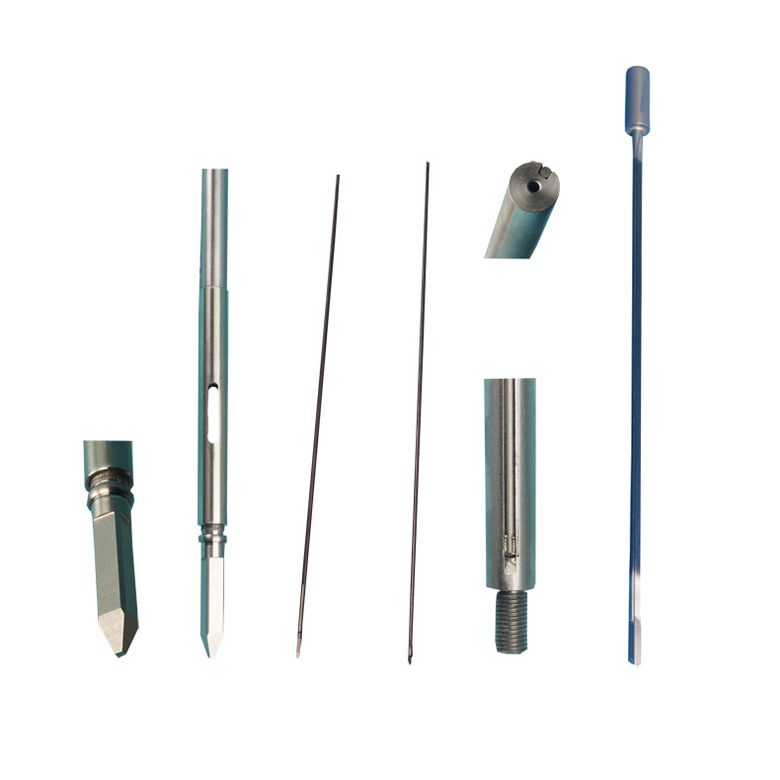

二,Products

Description

(Super-hard drill bits for high hardness

application)

For other size

specification and special micro-diameter, forming compound tooling, we can

process according to drawings or samples.

Machining case:

φ8.50 mill diameter (emulsified liquid), SKD11(HRC62°),rotation speed 1600r/min, f≤199mm/min,

depth

of drilled hole≤2.5*φD(mill Dia.), Precision of processed work piece ≥h9,

surface finish more than Ra1.6

Extra hard small diameter: mill Dia. φD (φ0.10-φ2.00mm), applicable

for machining of quenched steel of HRC≤62° and various high hard materials,

compound materials, the depth of drilled hole ≤6*φD(mill Dia.)

Referencing to the page footer, please provide

your sample and specify the detailed specification, material type, size

tolerance, drawing of semi-product and finished product, applied equipment,

equipment value (RMB, to judge its market value is rigid or floating),

monthly consumed quantity, type of original product and its deficiency, when

you make inquiry. What is the processed material and its HRC? Work piece

drawing and notes, and please supply us new and old bestperformed samples.

Samples: Is it easy to blunt or break or other

problems?

LZQ is possessed

of cutting-edge & comprehensive production system, as well as rich

producing & machining capability with different precision technology, so as

to realize high efficiency application.

三,Material / Characteristics

HRF 10 (For

super high wear-resistant):

Ultra

micro-grain quality carbide is ultra high wear resistant, but less

impact-resistant. It is applied in mid and low speed light cutting of various

materials that require ultra high wear resistance. Generally, it is applied in

good work condition, stable cutting, good part fixture and continuous

light-duty machining. Comparing with general tungsten steel, it has more than

4~6 times lifetime. Corresponding to ISO K10~K25/P10~P25.

VRA201:

Imported ultra micro-grain quality carbide, with excellent

impact-resistance and general wear-resistance. Generally applied in worse or

general equipment to machine materials of lower hardness (HRC≤25°), discontinuous

cutting and worse part fixture. Conforming to ISO K25, can replace machining of

materials like M42, ASP60, MPM, HSSCo10 etc, and can get 4-6 times lifetime, it

has higher performance/price ration. Comparing with SKH51, it has 15-25 times lifetime

and durability.

ASP60A :

mported ultra

high wear-resistant high-grade high cobalt powder steel, quenched:HRC70°±2°,

with excellent wear resistance and impact resistance. Comparing with

HSSE\HSS-AL and HSSCo, it has 4~8 times lifetime, and can guarantee uniformity

and conformity rate of machined products. It is often applied in general

equipment for machining various materials including Ni\Cr\Mo\Si\Ti) that are

hard to machine like high alloy\heat-resistant alloy\cast iron of

nickel-vanadium-titanium alloy\stainless steel. It is excellent machining tool

before heat treatment. It has excellent high temperature machining and

comprehensive performance, and allows higher cutting speed. The higher the

hardness of machined materials, the more remarkable the effect. Because its

roughness is not so good, it is not suitable for discontinuous cutting or for

using under processing system of insufficient rigidity, otherwise, cutter will

be hit or chipping will happen.

PR40:

super

micro-grain diamond tungsten steel, extensively applied, it can be applied in

medium speed cutting and finish cutting of various materials with HRC≤28°. It

has excellent impact resistance and general wear resistance, and has extensive

application. Generally, it is applied for thicker cutting, discontinuous

cutting and bad part fixture. After being coated, it has better result, can

machine various materials of HRC50°. Comparing with ISOK20&general tungsten

steel, it has 1-2 times lifetime and excellent wear resistance

+86-021-50327060

+86-021-50327060

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.

NO.1269 Plant, Jinhu Road, Jinqiao Export Processing Zone, Pudong New District, Shanghai, China.